SAFETY - QUALITY - CAPABILITY

SRC ELECTRICAL LLC, THE OEM’S SOLUTION FOR REMANUFACTURED ROTATING ELECTRICAL AND ELECTRONICS

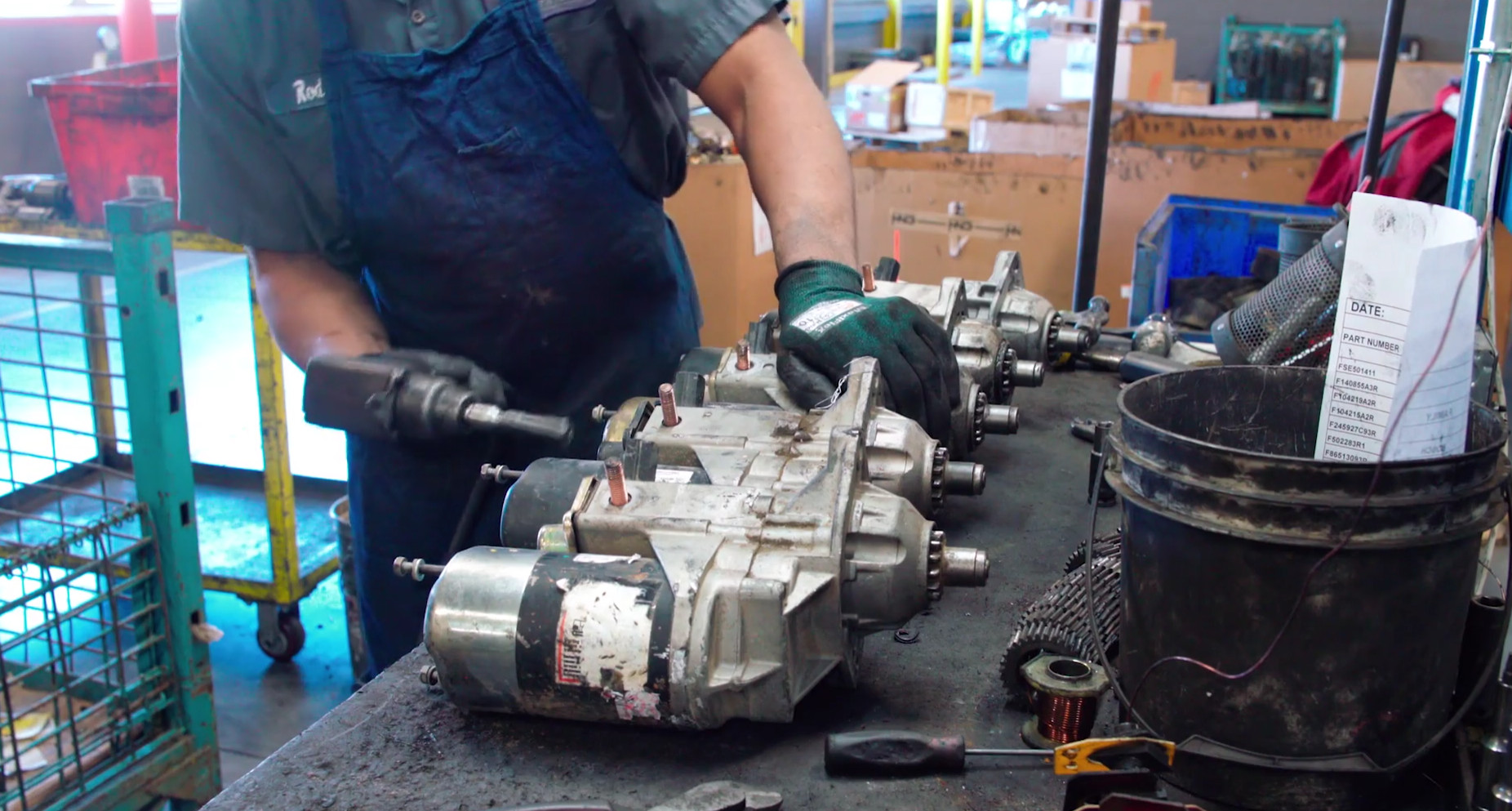

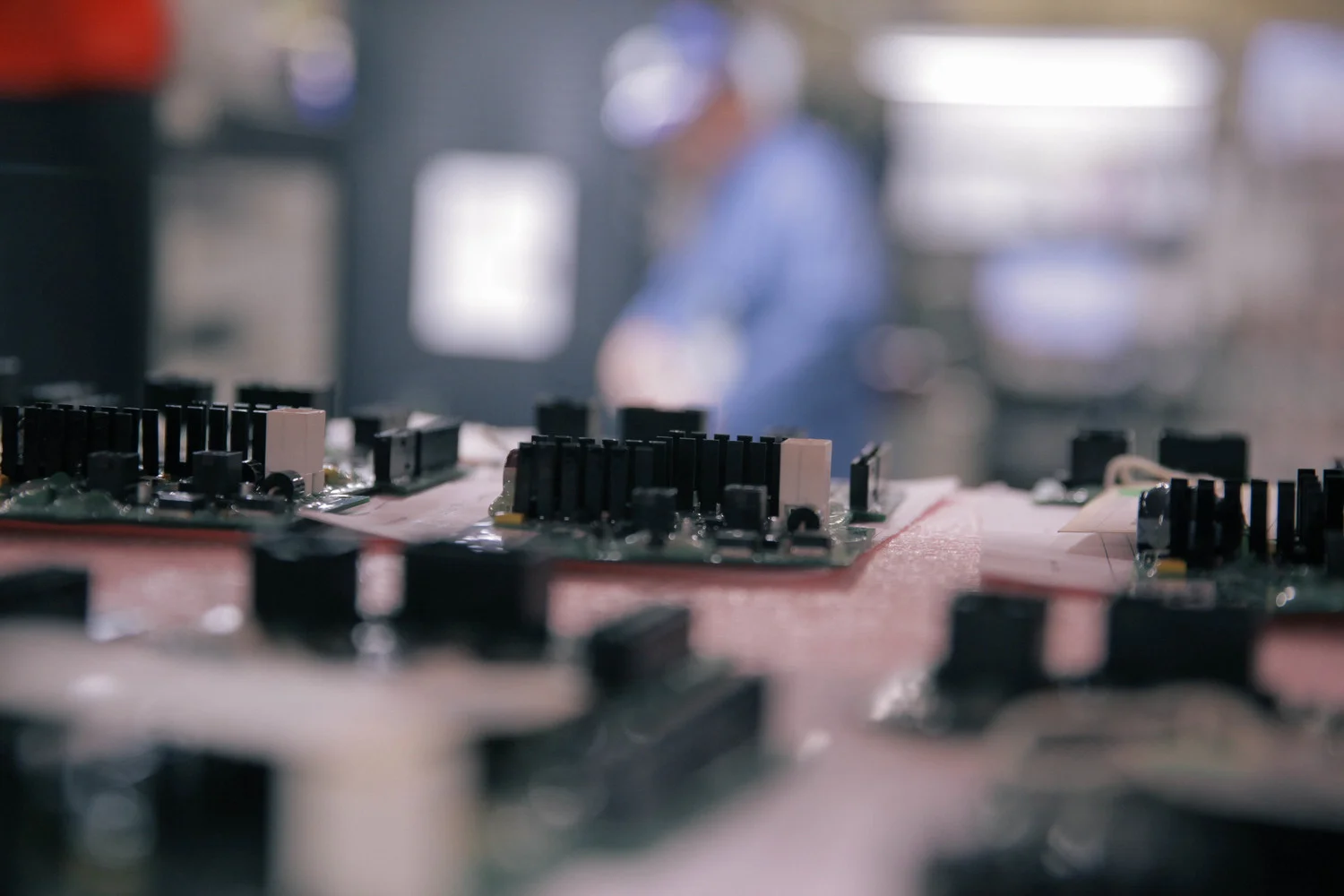

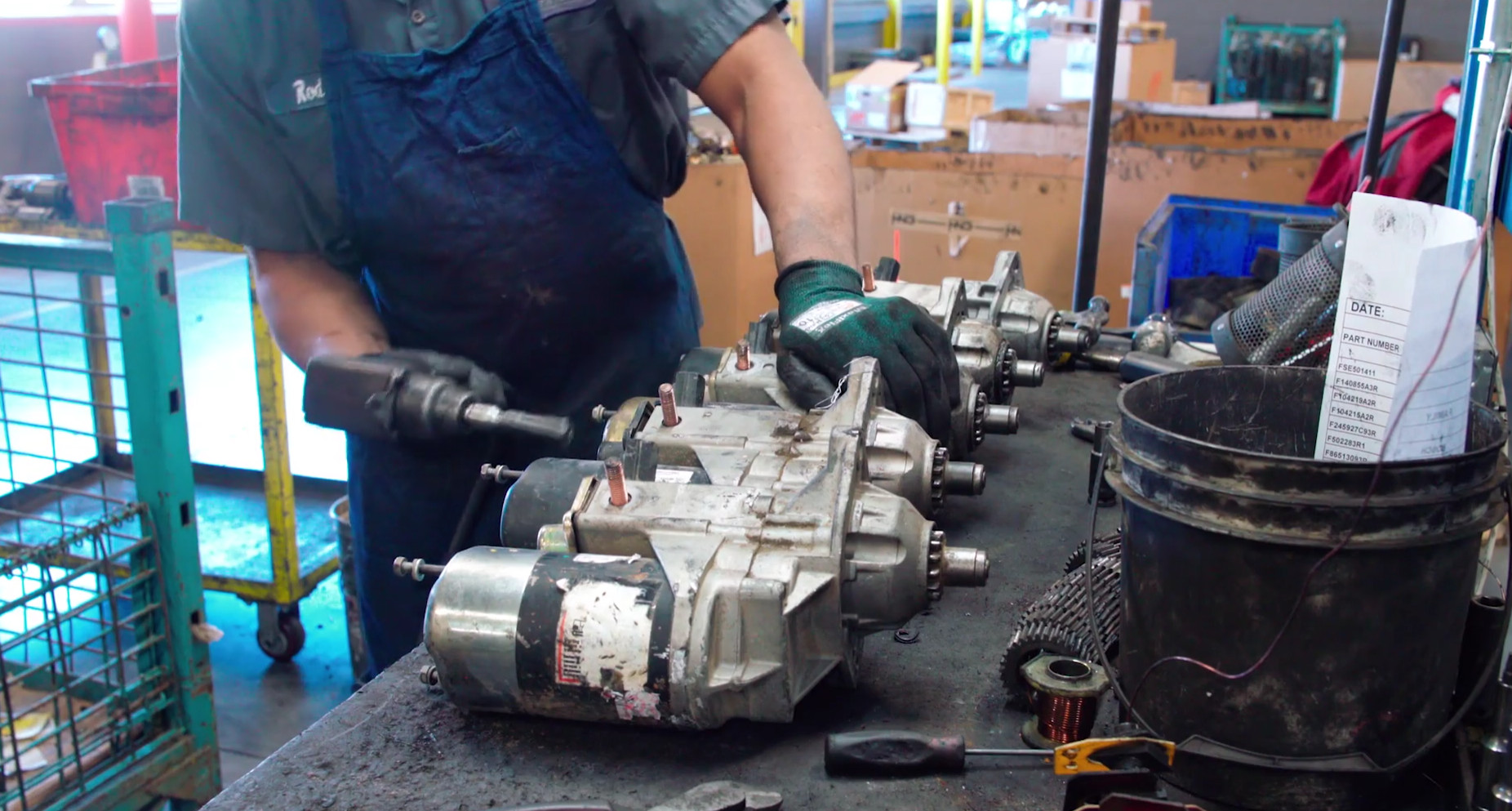

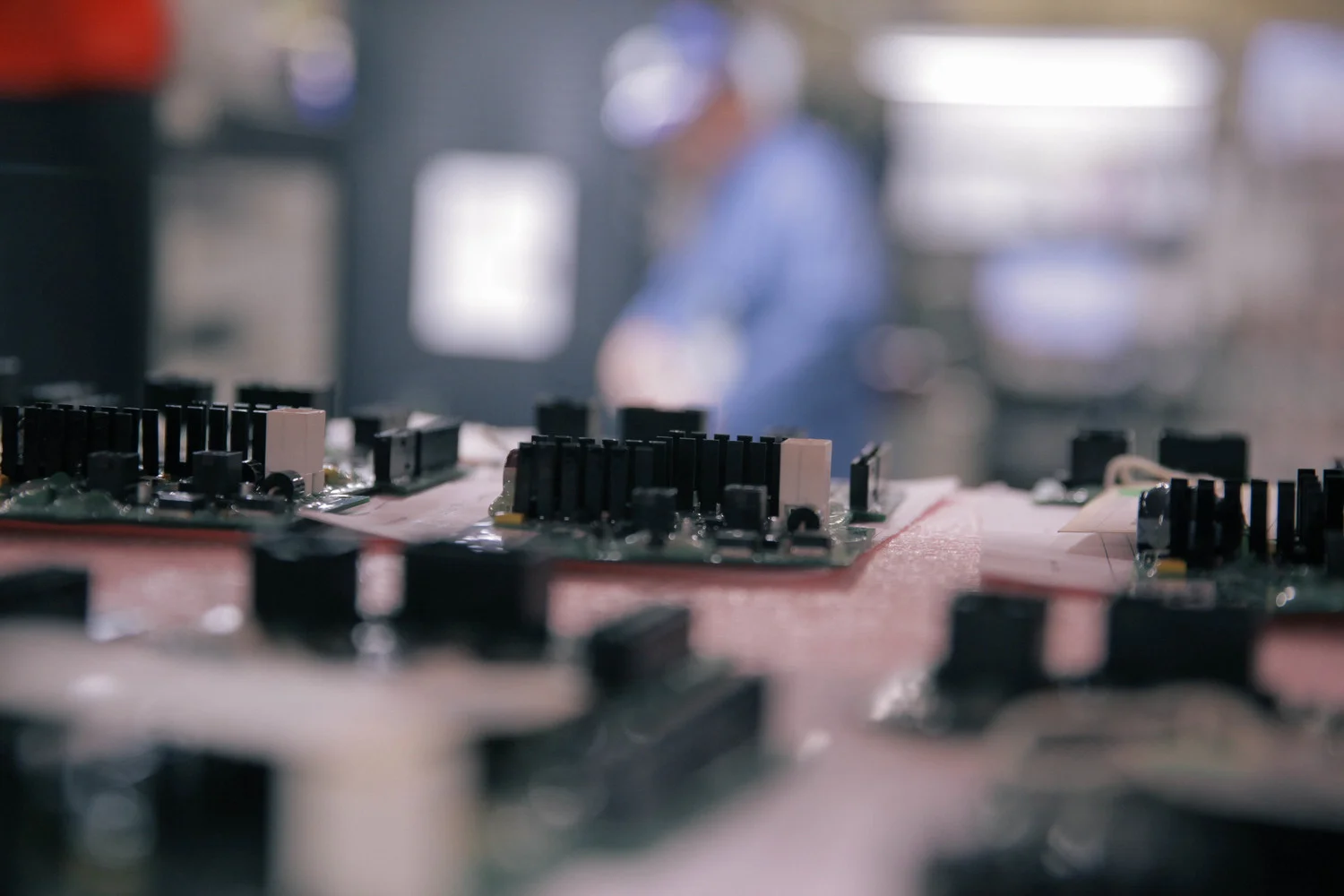

Since 1991, SRC Electrical has been serving the OEM’s full-line of rotating electrical products including, Starters, Alternators, Generators and Compressors. We’ve expanded our portfolio to include a full-line of remanufactured electronic products. Our current stable of remanufactured electronic products includes Electronic Control Modules (ECM’s), Displays & Instruments, Electromechanical Devices, and GPS Receivers & Antennas. In the global markets of Agriculture, Construction, On and Off Road Commercial Vehicles, and Industrial Power Systems, the SRC Electrical Team brings experience, expertise and leadership making us the premier provider for the OEM’s.

Through the installation of current product improvements, design upgrades and industry leading quality, our products set the bar for total customer satisfaction. We confidently back all our products with the OEM’s “new” part warranty. We re-engineer and configure every core to meet OEM specifications and ISO standards. Teaming up with OEM customers has proven to be a powerful combination and has provided us with the scale to deliver a competitive program with the highest level of quality.

WHAT WE DO:

Remanufacture Electronics & Rotating Electrical

SRC Electrical is a Remanufacturing Solutions Provider focused on working closely with OEM's to build successful rotating electrical and electronic offerings. Our suite of solutions include:

Remanufactured Electronic Products

Warranty Analysis/Mitigation

Repair Services

Legacy Manufacturing Services

Core Management

HOW WE DO IT:

A CULTURE OF OWNERSHIP

Committed to Financial Literacy for 100% of Our Associates Through the Practice of Open Book Management

ESOP Company - Employee-Owned Stock & Profit Sharing Plan

Member of OSHA's Voluntary Protection Program

Robust Wellness Program

Comprehensive Benefit Package

OUR COMMITMENT TO QUALITY:

Quality doesn't start with our warranty policies, it starts with the development of our products and services via the APQP Process. APQP involves up-front quality planning to ensure the finished goods meet or exceed the customer expectations through seven major elements:

Understanding the Needs of the Customer

Proactive Feedback and Corrective Action

Designing Within the Process Capabilities

Analyzing and Mitigating Failure Modes

Verification and Validation

Design Reviews

Control Special/Critical Characteristics

Our parent operating company, SRC Holdings Corporation, has been building successful remanufacturing organizations since 1983. Currently, SRC is focused on providing complete remanufacturing programs and solutions through its’ twelve (12) unique entities, each of which supports specific areas of the remanufacturing marketplace. These remanufacturing markets include core collection, complete gas/diesel engines, engine components (such as turbo chargers, fuel systems, hydraulics, rotating electrical, etc.), electronics (engine control modules, intelligent displays, turbo actuators, etc.) and OEM parts kitting programs. >> Learn More

Our CUSTOMERS Say...

“SRC Electrical is our primary source for rotating electrical and electronics solutions. Quality, speed to market, cost management, and accessibility are what make them standout to us. They understand our challenges and build solutions that work for us and our dealers. ”

“The SRC Electrical team sincerely impressed me during our initial product launch. The particular electronic controller will be going out of new production soon and will be no longer available. The reman option will keep our customers up and running for years to come... ”

QUALITY POLICY

We outperform the competition by providing high-quality Products that meet or exceed customer requirements while creating lasting relationships through continuous improvement of our Products and People.

Since inception we have invested heavily in the quality of our people, our processes, and our capabilities. Our quality starts with our associates, where we have recruited from a local talent pool of experts. Our processes are set to meet and (where applicable) exceed the requirements of the OEM's new product specifications. Finally, our products are rigorously tested to new product standards such as life cycle durability testing, in process thermal cycling, vibration testing, and air decay testing.

BEYOND THE STANDARD

ISO 9001:2015 Certification

Beyond the requirements of our QMS system, we offer best-in-class customer focused quality solutions which include:

Parts and labor warranty from the date of install

Less than 2% returns on all products

Component & Finsihed Good Life Cycle Testing

Field Validation

Thermal Profile Testing

Air Decay Testing

Continuous Improvement Program

In Process & Final Inspections

Full PPAP (Production Part Approval Process) requirements based on the AIAG standard, including PFMEA, Gage R&R, DPAR, Process Flow Map, Control Plan, Work Instructions, PSW, and other customer required data.

SRC Electrical is certified to the ISO 9001:2015 quality standard. We adhere strictly to the standard requirements such as:

Management Responsibility

Quality Policy, Business Management & Management Reviews

Resource Management

Training, Education and Certifications, Facility and Equipment Management

Measurement and Analysis

Customer Satisfaction, Internal Auditing, Process Monitoring & Improvement

Product Realization

Customer Requirements Management, APQP, Product/Process Validation, Production and Service Provisions, including Control Plans, Work Instructions, Engineering Change Management and Identification and Traceability.

Open-book marketing

There are two main types of costs we consider when evaluating a new remanufacturing program:

- Supply Costs - These are the primary costs relating to developing and releasing a reman program. The input costs are related to Engineering, Component Sourcing, Sales and Marketing and Production of our OE Clients Products.

- Demand Costs - While harder to measure, these costs are often more important as they pertain to costs related to the Customer base. For instance, if a customer does not have a remanufacturing option when they go to purchase... they go somewhere else for support. The appropriate economic term is Opportunity Cost. Availability, Development Time (or Time to Market), Engineering Capacity are all metric's which when efficient, catalyze growth.

The SRC Electrical team performs a full end-to-end assessment of both Supply and Demand costs when initiating a new program launch with an OE customer. Our mission is to maximize the efficiency in both types of costs to return the greatest available economic value back to our customers. We feel strongly that the best path for achieving maximized efficiency is to Open the Books. There is a great amount of lost value spent in haggling over price (a Supply Cost) and as a result we significantly increase our time-to-market (a Demand Cost). Recognizing this we are upfront about our Supply Costs and work with our OE customers prior to program launch on a fair standard margin for a reman program, such that we maximize our customers benefit.

Learn more about our approach and how Open Book Marketing can work for you in our Business Strategy.